{{propApi.title}}

{{propApi.text}} {{region}} Change location{{propApi.title}}

{{propApi.successMessage}} {{region}} Change location{{propApi.title}}

{{propApi.text}} {{region}} Change location{{propApi.title}}

{{propApi.successMessage}} {{region}} Change locationMember and guest login

Enter your email and password to access secured content, members only resources and discount prices.

Did you become a member online? If not, you will need to activate your account to login.

If you are having problems logging in, please call HIA helpdesk on 1300 650 620 during business hours.

Forgotten password

Need some help?

If you are having problems logging in, please call HIA helpdesk on 1300 650 620 during business hours.

If the email address you have entered is registered, you will receive an email with further instructions.

Become part of the HIA community

Enables quick and easy registration for future events or learning and grants access to expert advice and valuable resources.

Create a guest account

Enter your details below and create a login

Changes to AS NZS 3000 2018 Wiring Rules Standard

Changes to the new version of AS/NZS 3000

The new version of AS/NZS 3000 Wiring Rules Standard (Electrical Installations) contains over 200 changes and expands coverage on electrical installations, improves safeguards, takes account of new technology and clarifies certain ambiguous requirements from the previous version.

The changes include:

- mandatory RCD requirements for protected circuits and alterations and repairs clarified

- changes to installation requirements for cables that pass through bulk insulation

- revised requirements for exclusion zones for socket outlets and light switches in bathrooms and laundries

- enhanced testing and verification requirements

- new requirements for exclusion zones for socket outlets and light switches adjacent to cooktops

- new switching requirements for cooktops and hot water heaters

- revised earthing requirements and enhanced earthing requirements for swimming pools

- enhanced requirements for switchboard installation and minimum clearances

- installation requirements for electricity generation systems (for examples roof mounted PVs) in line with those in other Standards

- new electrical vehicle socket outlet requirements

- new figures added and existing figures updated and general improvements to language to assist interpretation.

A more detailed description of the major changes applicable to residential buildings is provided in Appendix A.

Major changes in more detail

All new (including alterations/renovations) domestic and residential installations, the final sub-circuits are to be RCD protected, with the exception of additional new work to existing lighting circuits. Air-conditioners, electric hot water systems, hotplates and ovens require a safety switch.

In commercial and industrial environments, the requirement for final sub-circuits are 32 amps (increased from 20 amps) of:

- socket outlets (1,2 & 3 phase) and lighting circuits

- direct connected handheld equipment

- direct connected stationary equipment in a high-risk environment.

All other final sub-circuits not in excess of 32A are to be assessed RCD compatible and if so ‘should be’ RCD protected.

There are exceptions that can be applied where the equipment has leakage current that would impair reliable operation. A risk assessed appropriate alternative method of installation and equipment selection will be needed to achieve the same level as RCD protection. This could include additional mechanical protection, a separated supply or earth monitoring protection.

Clause 2.6.3.2.2 of the Standard addresses domestic and residential installations and clause 2.6.3.2.3.3 addresses the requirements for additional protection.

The existing requirements of the protection of electrical cables has been clarified and additional methods of installation will now be required. In areas where cables are not easily accessed in a roof space, electrical cables will need some form of fixing by clipping or tying.

Where, in a roof space, electrical cables can be stood on, a suitable form of covering is required to prevent the electrical cables from being damaged. Clauses 3.3.2.6 and 3.9.3.3.2 address these requirements. Appendix H provides additional guidance with examples.

Where cables are installed within walls and ceilings, a dispensation from additional mechanical protection has been withdrawn. An exclusion zone from requiring mechanical protection of 150mm from a ceiling or wall has been deleted. This will require additional work to add a suitable barrier or enclosure to protect cables that are not installed with RCD protection. These cables may include consumer mains, additional switchboard main supply cables and the like. Clause 3.9.4.2 addresses these requirements.

Clause 3.10.3.1 sets out requirements for roof top installations using a wiring enclosure to ensure the installation does not impede the ability of the roof to clear water by its initial design. This would apply to solar PV systems, hot water and air-conditioning installations and the like.

Cable tray enclosures with removable lids and conduit piping installed on a roofing surface may need additional mechanical standoff supports to ensure debris and other obstructions will not impede the ability of the roof to clear water drain paths.

Clause 4.1.3 sets out a new requirement to ensure electrical equipment located on the outside of buildings may require a specific Ingress Protection rating (IP) – e.g. installing a standard socket outlet on the outside wall of a building may not meet this requirement. A weather-proof socket outlet will be required (IP 33 minimum). This will also apply to fences and property boundary walls.

In specific environments where higher water pressures or exposure to storm conditions are known, a higher IP rating may also be required.

There are exceptions for metering enclosures and overhead supply cable connection boxes having a lesser IP rating (IP 23) and are outlined in the Standard.

With recessed halogen lighting and lighting control gear implicated in a number of fires, clause 4.5.2.3.4 provides guidance for an Internally Covered (IC) rating, a new classification system for recessed luminaires. Each classified luminaire type is given an identification prefix, which enables the purchaser to select the correct recessed light fitting for the type of ceiling it is to be installed. New symbols are included to identify IC or Non-IC type luminaires.

Clause 4.5.2.3.1 also identifies a minimum separation of 100mm to building elements or insulation and 50mm to the control gear, while clause 4.5.2.3.2 identifies where warning signs are required.

Clause 4.7.1 has an added requirement that the mandatory requirement for a switch to turn off the appliance cannot be mounted on the appliance. There is also a note that the switch should be mounted within 2m of the cooking appliance.

A new clause 4.8.2.3 requires all hard-wired hot water heaters to have an isolator installed adjacent to the appliance. As with cooktops and air-conditioner isolators, they cannot be mounted on the appliance.

Also be aware that isolators are required to have a manufactured facility to secure the switch in the ‘off’ position so will be more expensive than the cooktop type which has no such requirement.

The Standard provides examples for the requirement of lockable isolators and where warning labels are required – e.g. split unit A/C compressor unit requires the installation of a lockable isolator and the indoor unit requires a warning label indicating the isolator does not isolate any ancillary equipment.

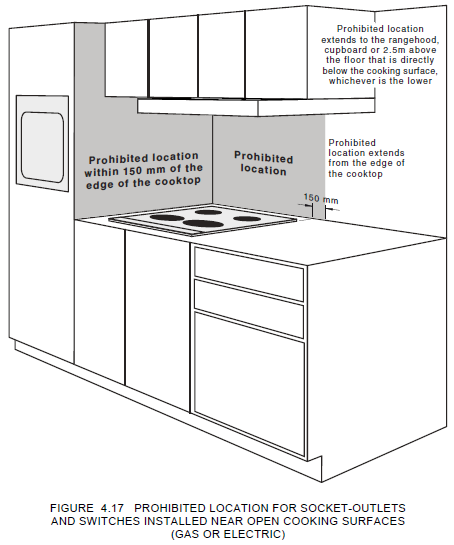

A new clause 4.7.3 requires an exclusion zone of 150mm horizontally and a vertical height determined by the kitchen layout. No socket outlets or light switches can be installed in the exclusion zones identified by the figure shown below.

This new clause is required to ensure electric powered cooktops have the same requirements as the Gas Standard, which applies to the installation of a gas powered appliance (AS/NZS 5601).

Extract from AS/NZS 3000

Clause 5.4.6 has been reworded to now include earthing of all building conductive framework regardless of the building classification. The size of the earthing conductors will be determined by the size of the electricity supply cables. The previous edition only required bonding to framework on domestic steel-framed homes.

Clause 5.6.2.5 sets out minor changes to the equipotential bonding requirements for bathrooms and swimming pools which will mean different methods or ways will need to be used to connect the earthing cables to conductive building materials. Where alterations are made to an existing bathroom installation, the Standard highly recommends installing bonding conductors.

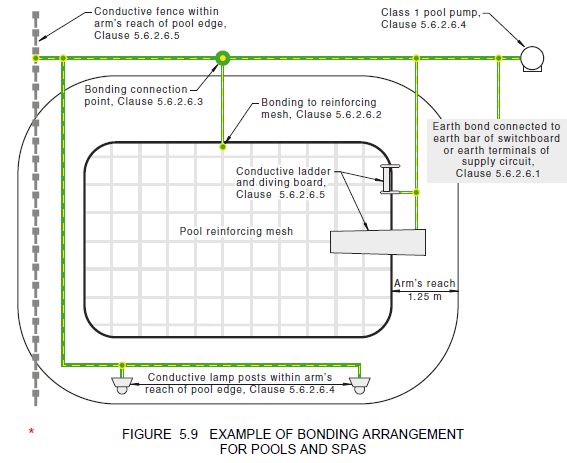

Clauses 5.6.2.6.2 and 5.6.2.6.3 set out the need for swimming pool bonding on all concrete reinforced steel pools and steel framed above ground pools. Some fibre glass pools also have steel reinforcing which will require bonding. An allowance has been made where the concrete pool reinforcing steel is continuously connected to the reinforcing steel in the main floor or slab of a building, only one bonding conductor is required for both bathroom and pool bonding requirements.

The requirement to bond any conductive building components or pool accessory that is within 1.25m of the pool edge within clause 5.6.2.6.5 has now been redefined. The requirement to bond is for any component in excess of 100mm that is exposed. For example, a pool fence spigot that may be 300mm in total length but only 95 mm is exposed will be exempt bonding.

A new diagram, Figure 5.9, illustrating one method of constructing a bonded earthing system to meet the requirements of equipotential bonding has been added. Note that the pool reinforcing tail to be connected to the general earthing conductors require that termination to be accessible. All other tails from the required earthing of fittings and fixtures need not be accessible.

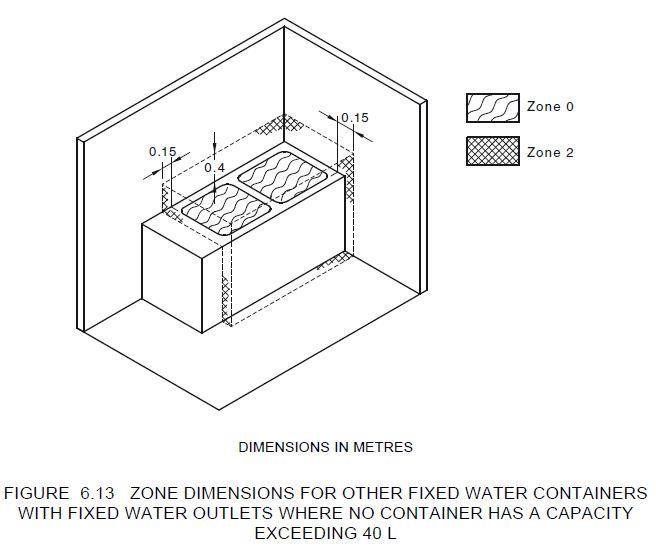

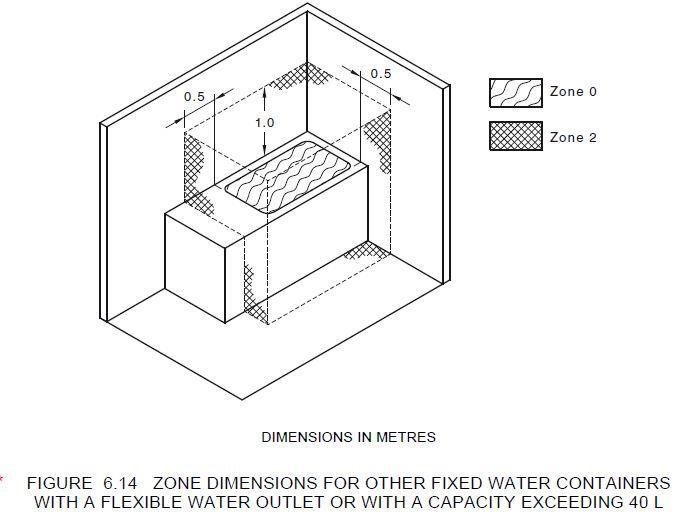

Figures 6.13 and 6.14 illustrate a change to a 40-litre capacity from the previous 45 litres for the purposes of determining exclusion zones (where socket outlets and light switches cannot be installed).

New revised drawing Figures 6.5, 6.6, 6.8 and 6.11 showing examples of the classified zones where barriers or a ceiling mounted plumbing connection is used. Classified Zones restrict the ability to install light switches, socket outlets & electrical accessories in these locations.

Clause 6.3.2.2.1 addresses the new change to the size of the pool or tub that reflects the industry reference to spa baths and the like which are now manufactured to an increased ability to contain 680 litres of water. The requirements for spas and tubs are different to that of baths and shower cubicles so the change was to ensure a specific definition can be applied for the correct product type.

Clause 8.3.3.2 has been rewritten to identify the mandatory requirement to test extra low voltage where they exist. This is a new requirement that will incur additional time for work performed where ELV wring is installed.

Clause 8.4 was amended to change ‘should’ to ‘shall’. It now is mandatory to label the switchboard with an indelible label that will need to last the lifetime of the installation. A handwritten date can also be used with the words ‘Installation Certification’ that is of a permanent type and will last for the expected life of the installation. It is not required when any subsequent works are performed.

Clause 3.9.8.2.1 sets out a new requirement to ensure electrical cables for one customer are not installed in a common conduit or sealed enclosure with another customers supply cables. The underground supply cables can be installed in the same trench, but will need to be in their own specific conduit or sealed enclosure.

The same would apply in a duplex or other type of commercial installation where the supply cables for each tenancy are using the same method and route. The cables are to be installed in separate conduits or sealed enclosures.

Clause 3.9.8.2.2 sets out requirements for where different installation mains cables and sub-circuit cables are installed in a shared enclosure, specific requirements are required. This may require larger enclosures due to spacing distances, fire proofing or barriers.

Amendments have been made for increased clearances of 1m (increased from 600mm) from the outside of a switchboard’s finished surface to building structures and walls. The clearance requirement is applicable to all switchboards irrespective of current capacity, except those in single domestic installations.

Download your copy today!

AS/NZS 3000:2018 Electrical installations

AS/NZS 3000:2018 Wiring Rules enhance installation coverage, improve safeguards, integrate new tech, and clarify ambiguities.

Find the latest expert advice, guides and much more!

Was this page helpful?

Building it right topics

Can’t find what you need, check out other resources that might be closer to the mark.

Silica Awareness

Find out more about what silica is, how to work safely with products containing silica, what tools and systems exist, as well as where to get further information

Beyond 7 Star Energy Efficiency in Victoria

Gain an understanding of Energy Efficiency requirements, including new standards and requirements coming in Victoria, in 2027.

CPC50220 Diploma of Building and Construction (Building)

This diploma course is designed for building and construction professionals who wish to gain valuable skills in managing medium rise construction projects.

Estimating and Quoting

Get the knowledge and skills required to accurately calculate and estimate material, labour and equipment costs, as well as business overheads, margins and other costs for small residential and commercial construction projects.